Hoppers

Storage

capacity

11 - 1,644

tons

Hoppers

Diameter

2.7 - 11

meters

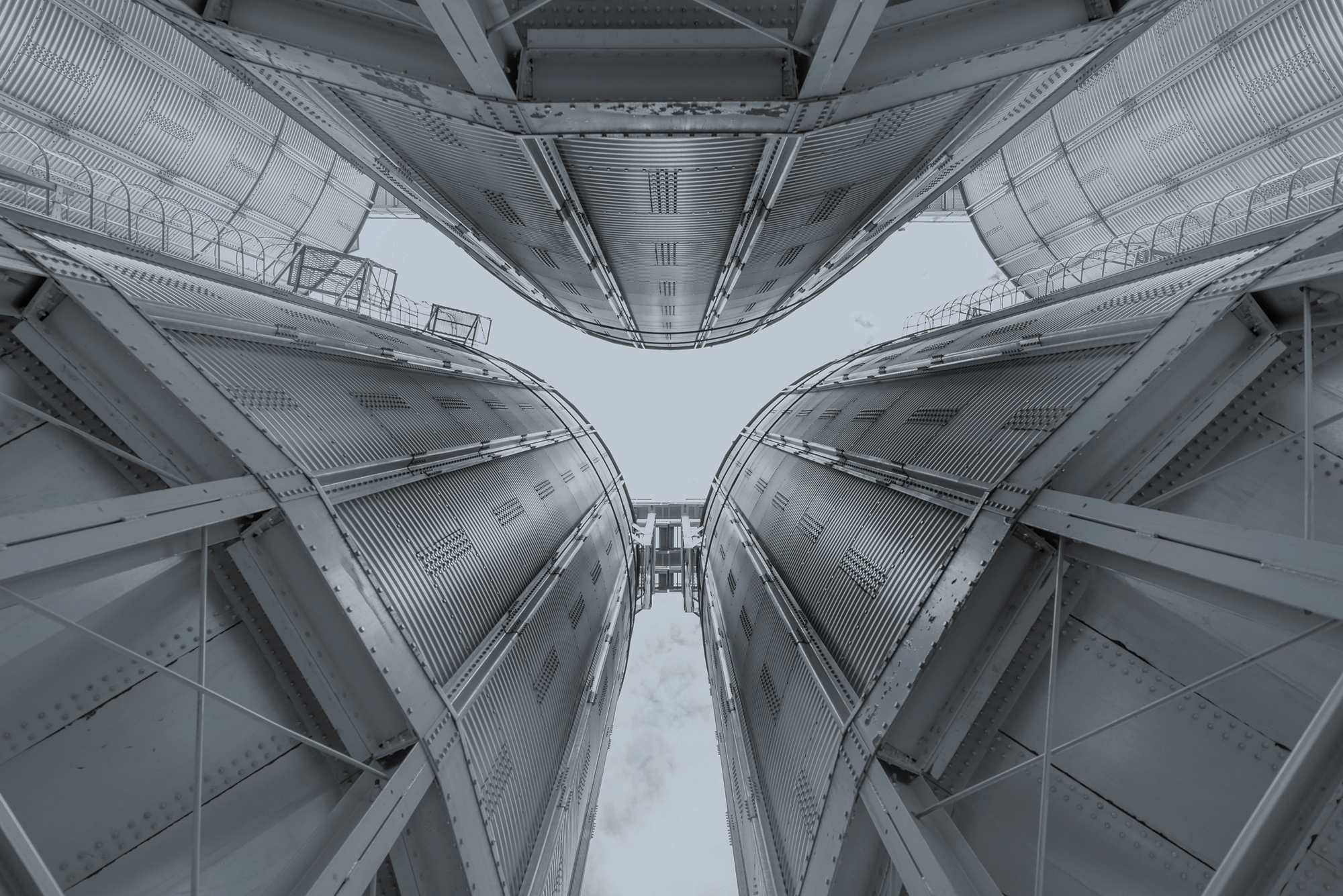

Hoppers

Hoppers

Model range

KMZ Industries produces the widest model range of hoppers in Ukraine:

- 3 model ranges: Вrice-Вaker, SMVU, Variant Agro Build;

- 7 types of silos;

- 23 modifications of silos.

Hopper capacity from 11 to 1,500 t of grain. Funnel tilt angle: 45°, 55°, 62°, 65°. Silo diameter — from 2.7 to 11 m. Diameter increment of Brice-Baker silos is 1 m, which enables the silo to fit into any layout of the site.

Storage

Hoppers manufactured by KMZ Industries are used for storing humid grain

for rapid unloading.

They are also suitable for storing compound feed, flour and oil meal: for these products, we produce hoppers with funnel tilt angle 62° and 65° and a strengthened design. Due to special solutions developed by our engineers, it is possible to avoid freezing and sticking of products with high bulk density (hard-to-flow products) inside the hopper.

Our hoppers ensure the long-term consistent quality of the stored grain using:

- variability of aeration system (selected directly for each project);

- advanced temperature control system: digital multipoint temperature transmitters with layer-by-layer temperature control enable the information to be brought to a PC or gadget using specialized software; multipoint temperature transmitters are installed at intervals of 1.5 m.

Quality

Silos are produced of high-quality, durable galvanized steel from European manufacturers. The steel grade is S350GD with zinc coating Zn 275, Zn 350, Zn 450, and Zn 600 (according to the project’s requirements).

Design loads comply with DIN, DSTU, DBN, and EUROCODE.

Assembly

Hoppers produced by KMZ Industries are easy and fast to assemble due to the accurate geometry of bolt connection holes and the presence of visual markers of panel thickness (BBK models).

Warranty

The guaranteed quality of the equipment manufactured by KMZ Industries is confirmed by our customers’ operational experience of more than 10 years.

Safety and ergonomic

For operational safety and ease of use the silos are equipped with:

- upper grain limit level sensors;

- inspection and service hatches;

- ergonomic ladders with handrails;

- ergonomic scaffolding and ladders with handrails and guardrails for ease of use.

Accuracy and strength of bolted joints

Geometric accuracy of bolt holes in panels and ribs. Fastening are used M10 and M12 bolts, strength grade 8.8, complete with nuts, conical washers and gaskets.

Please contact us for any questions you may have concerning our company, products or services.

Fill out the feedback form or call +38 (050) 435 76 97.

Other types of Siloses

Projects

POPULAR

ПОНАД 5000 ПРОЄКТІВ

ВТІЛЕНО В СВІТІ

CONTACTS

HEAD OFFICE

+38 (05346) 221 38

2 Sergii Nihoian St., Karlivka, Poltava region, 39500, Ukraine

SALES OFFICE

+38 (050) 435 76 97

sales@kmzindustries.ua ,

2V Mykilsko-Slobidska St., office 157, Kyiv, 02002, Ukraine