Brice-Baker grain dryers

Capacity

9 - 437

tons/hour

Range of

190

models

Brice-Baker grain dryers

KMZ Industries & Brice-Baker

In 2012, KMZ Industries acquired the British company Brice-Baker, one of Europe’s leading manufacturers of elevator equipment. This step allowed us to offer our customers a new generation of products that best meet their growing needs for performance, reliability, and cost-effectiveness. Today, the entire range of Brice-Baker grain dryers (190 models) is manufactured at the KMZ Industries plant in Ukraine.

Brice-Baker grain dryers in Ukraine

To dry grain rapidly and efficiently, high-quality, powerful equipment is required. Brice-Baker grain dryers from KMZ Industries fit the bill.

First, a little history. Brice-Baker grain dryers were developed in England by specialists from the company of the same name, but in 2012 we acquired this enterprise along with all its intellectual property. Since that time, we have been manufacturing European-quality grain dryers in Ukraine under the same name. Now more about the dryers themselves.

Characteristics and price of Brice-Baker grain dryers

To buy a grain dryer, you first need to know its characteristics. Brice-Baker dryers are:

- high productivity;

- cost-effectiveness;

- environmental friendliness;

- ability to dry all types of grain crops;

- wide range of models;

- safety.

The productivity of Brice-Baker grain dryers reaches 437 t/h, while the productivity of many grain dryers does not even reach 100 t/h. With this grain dryer, you can dry large volumes of grain faster.

Sustainability. How much grain can a dryer process when burning 1 m³ of gas? This is an equally important factor, because you only pay for the grain dryer once, but fuel costs are a regular expense. Brice-Baker shaft grain dryers provide fuel savings of up to 15% and electricity savings of up to 40%.

Sustainability. Grain dryers in this line are equipped with an aspiration system with an efficiency of 97.85% as standard. What does this mean? Firstly, safety — dust ignites as easily as gunpowder, which can lead not only to the grain catching fire, but also the entire dryer. Second, the dryer does not release much dust outside, and the noise level is reduced to 48 dB, so it can be located near populated places.

The presence of an aspiration system also enables Brice-Baker grain dryers to dry all types of grain crops. Sunflower seeds and rapeseed, for example, produce much more dust than wheat, which increases the risk of fire. In such cases, it is safer to dry these crops in Brice-Baker grain dryers.

The wide range of Brice-Baker models includes 190 grain dryers with a capacity of 9 t/h to 437 t/h. This means that we can select a model for any customer according to their needs.

Safety. Brice-Baker dryers are equipped with overheating (fire protection) sensors, grain level sensors, turbo fan vibration sensors, emergency product discharge hatches from the grain shaft, and temperature sensors as standard. When the maximum permissible temperature is exceeded, an audible signal is emitted, the burners are switched off, and the dryer is switched to emptying mode. After unloading the product, the shaft is cooled using the fire extinguishing system’s dry pipes (optional). When the turbo fans become dirty, they begin to vibrate more strongly. This is indicated by the vibration sensors. Please also note that:

- Brice-Baker grain dryers are made of high-quality galvanized steel manufactured in Europe.

- Dryers in this model line operate not only on gas burners, but also on heat generators using alternative fuels. In addition, it is possible to connect two types of fuel simultaneously — alternative and traditional.

- Brice-Baker grain dryers are equipped with fan service platforms, which greatly facilitate their inspection and maintenance.

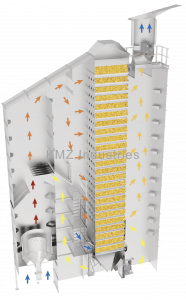

Recuperation in Brice-Baker grain dryers

- Part of the spent hot air with the lowest moisture and air content is fed through a fan into the hot air chamber for reuse after cooling.

- Fuel consumption is reduced by up to 30% compared to grain dryers without recovery.

- Air is fed into the hot air chamber bypassing the gas burner. This ensures fire safety.

| Air from the environment | |

| Air heated by a burner | |

| Air heated by a burner mixed with recovered recuperation | |

| Exhaust air saturated with steam | |

| Recovered air for reuse |

Dust suppression system

There is no dust escaping from the drying shaft when unloading grain.

- Maximum dust accumulation in the exhaust air chamber occurs during unloading when grain moves quickly through the grain dryer shaft.

- To prevent dust emissions into the atmosphere during unloading, the dampers installed under the fans are closed simultaneously with the opening of the unloader.

- After unloading, the dampers under the fans are opened and the drying process resumes.

Important! To prevent dust ignition, grain dryers with this type of dust collection system need to be cleaned more often than grain dryers with cyclones.

Types of fuel used by the Brice-Baker grain dryer

The Brice-Baker dryer can run on natural gas, diesel, and alternative fuels (pellets, wood chips, etc.). In addition, it is possible to connect two types of fuel simultaneously.

This solution has already been implemented at the Vozrozhdenie agricultural enterprise. Choose one or another type of fuel depending on its availability for your elevator.

For example, here is a comparative table of the cost of drying corn in a Brice-Baker grain dryer using different types of fuel (10,000 tons of grain, with moisture content reduced from 23% to 14%):

Configuration and price of Brice-Baker grain dryers in Ukraine

If you are interested in our grain dryer, the price will be calculated individually according to your requirements. This is due to the performance and configuration. By default, the set includes the grain dryer itself with an aspiration system, all level, overheating, and treated air temperature sensors, insulation of the dryer body and roof, air flow rate adjustment dampers, an external ladder with rest platforms, a Balma compressor (Italy), an internal ladder with service platforms, and adjustable partitions for regulating the cooling zone.

Other services from KMZ Industries

In addition to manufacturing grain dryers, KMZ Industries provides the following services:

- installation of facilities or supervision of installation if you wish to do it yourself;

- technical inspection of facilities, troubleshooting;

- training of employees in the operation of grain dryers and other equipment from KMZ Industries.

About funding

For those who have decided to purchase a shaft grain dryer from KMZ Industries, we have some good news. Our customers can obtain financing at favorable rates and preferential terms from one of our partner banks.

For more information about the grain dryer or to receive a cost estimate, please fill out the feedback form or call us at +38 (050) 435 76 97.

Advantages of Brice-Baker grain dryer

Higher energy efficiency compared to the forced type of ventilation

S350GD strength galvanized steel from European manufacturers (zinc coating up to 600 g/m2).

Grain load level control

Adjustable size of cooling zone through movable partitions

High-quality gas burners of German, Italian and domestic manufacture*

*Ability to use various types of fuels

Uniform grain motion without causing damage to grain

Interactive operational control

Aspiration system captures up to 97.85% of dust

Careful drying of grains

Environmental compatibility and production effectiveness

Gas consumption from 0.9 m3/t%

Reliability and high productivity

Discharge hopper with inspection hatch and windows

Protection from thermal shock and grain damage during heating

Models with production capacity from 9 to 437 t/h.

Other types of grain dryers

Projects

POPULAR

OVER 5000 PROJECTS

DEVELOPED WORLDWIDE

CONTACTS

HEAD OFFICE

+38 (05346) 221 38

2 Sergii Nihoian St., Karlivka, Poltava region, 39500, Ukraine

SALES OFFICE

+38 (050) 435 76 97

sales@kmzindustries.ua ,

2V Mykilsko-Slobidska St., office 157, Kyiv, 02002, Ukraine