Productivity during

coarse separation

200

tons/hour

Sieve area

up to

20

m2

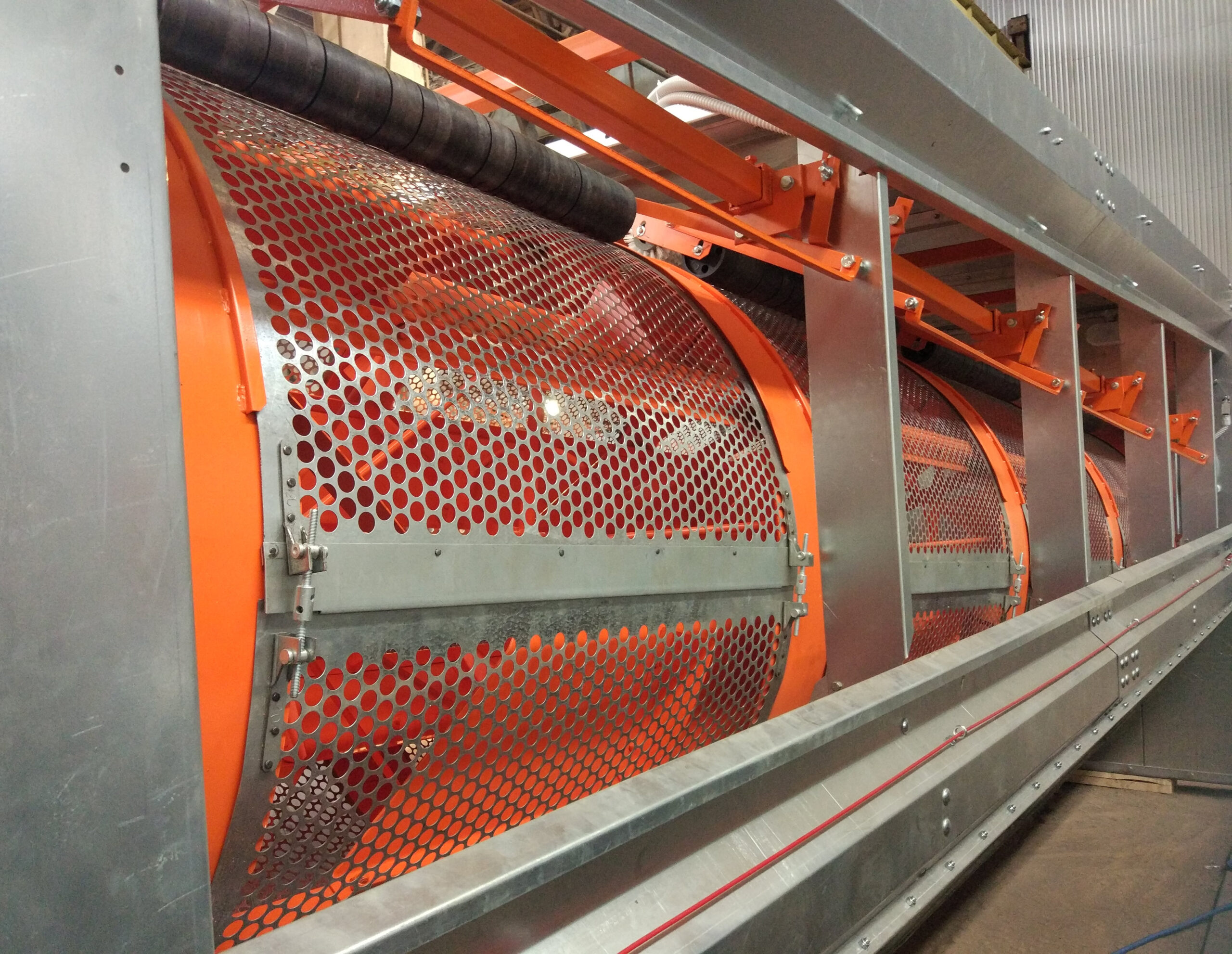

Grain cleaners

KBS grain cleaner

KMZ Industries grain cleaner are combined the functions of:

- scalperator (grain pre-cleaning),

- separator (primary and secondary cleansing)

- calibrator (separation into fractions according to the mesh size).

Continuously adjusted product traverse speed on the screen and reduced vibration assure easier separation of grain and oil crops while moving through the screen in the course of cleansing. This allows working even with crops, which are very hard to cleanse.

Versatility of the separator gives the opportunity to reduce the number of utilized equipment and simplify the maintenance.

Functions of grain cleaners

KBS grain cleaner removes light, small and large impurities, which are separated by air and punching sieves, from the grain mass.

The possibility of using 5 different technological schemes:

- aspiration;

- pre-cleaning;

- separation;

- calibration;

- universal scheme.

3 KBS separator models

| Number of sieves | Area of sieves, m2 | Maximum output*, t/h | ||

| Preliminary | Primary | Secondary | ||

| 3 | 12 | 75 | 50 | 10 |

| 4 | 16 | 150 | 100 | 20 |

| 5 | 20 | 200 | 150 | 30 |

* — for wheat at humidity up to 16% and impurity content up to 10%

General view and scheme of the technological process of the KBS complex drum separator

| 1 — drum 2 — sieve cleaner 3 — pneumatic separating channel 4 — fan | 5 — dust chamber 6 — light impurities unloading the device 7 — outlet nozzle 8 — receivers for separated products |

Distinctive features of the KBS grain cleaner are as follows:

- The possibility of using different technological schemes

- Flexible setting of the grain cleaner movement

- Quick and easy sieve replacement

- No dynamic loads and dust

Please contact us for any questions you may have concerning our company, products or services.

Fill out the feedback form or call +38 (050) 435 76 97.

Advantages of KMZ INDUSTRIES separators

Cleaning of all kinds of grain, leguminous and oil crops

Quickly detachable galvanized sieves with efficient system for removing light admixtures

No vibration, noise or dust

Careful cleansing of grain

Effective cleansing with wet grain

Projects

POPULAR

OVER 5000 PROJECTS

DEVELOPED WORLDWIDE

CONTACTS

HEAD OFFICE

+38 (05346) 221 38

2 Sergii Nihoian St., Karlivka, Poltava region, 39500, Ukraine

SALES OFFICE

+38 (050) 435 76 97

sales@kmzindustries.ua ,

2V Mykilsko-Slobidska St., office 157, Kyiv, 02002, Ukraine