Suppliers

Galvanized steel from SSAB

KMZ Industries has been cooperating fruitfully with the Swedish Metallurgical Company SSAB, one of the best European producers of galvanized steel, for more than 10 years. The total capacity of the giant’s plants located in Sweden, Finland and the United States is almost 9 million tons of steel per year. SSAB shares are listed on the Stockholm stock exchanges among the “blue chips” (the largest, most liquid and reliable companies). And 14,500 employees work in more than 50 countries around the world.

What does KMZ Industries Buy?

KMZ Industries buys from SSAB the world’s best galvanized metal – SSAB Domex350GD steel with zinc coating Zn 275, Zn 350, Zn 450, Zn 600, because its quality depends on how long our equipment will work.

Why SSAB steel?

Metal is made from its own ore. Manufacture know “steel history” from the moment of its extraction: they bring it themselves, they melt it themselves. Carefully monitored entire process. The Swedes are meticulously picky about steel. Only Swedish mines with high iron content. Only the purest iron and not without scrap.

Manufacturers who do not have their own raw materials and buy iron, firstly roll it, then etch it, and then send it to the so-called Training stands. Unfortunately, not everyone has such crates, hence the “banana-like”, different metal thicknesses and other surprises at the exit. We’ve never had such problems with SSAB! No zinc peels or shortcomings. Only the highest quality zinc according to European standards.

The factory cares not only about the quality of products, but also about packaging. They are not going to compromise and reduce the cost – after all, it reliably protects products both during transportation and during storage in a warehouse.

Galvanized steel from Thyssenkrupp

Thyssenkrupp Steel is one of the world’s leading manufacturers of premium Flat Rolled Products, the steel production innovator in the most modern and complex areas, and our respected partner.

The hot-dip galvanized steel roll from ThyssenKrupp, which we purchase for the production of elevator equipment, combines the advantages of serial (float) and continuous galvanizing. Hot-rolled steel strip is galvanized in a continuous process, and unlike the cut strip galvanized in the traditional hot-dip way, its side surfaces (edges) are also zinc-coated for additional corrosion resistance. Even such mechanical engineering giants as Volkswagen and BMW trust the quality of this metal.

The innovative metal coating “zinc + magnesium” produced by ThyssenKrupp is used for the manufacture of silo roofs to ensure maximum strength and durability of this most wear-prone part of equipment. Compared to conventional galvanized steel, the powerful magnesium-zinc alliance increases the corrosion resistance on the roof by 7 times. At the same time, the weight of the coating is less and also with self-healing effect, which protects edged edges, scratches or punched holes.

The alloy with this coating is certified according European requirements, does not contain harmful elements and 100% recyclable. So, its development is a unique part of industrial climate protection, which implemented by ThyssenKrupp. This largest German producer plans will complete the new “green transformation idea” plant by 2025. Thanks to the use of environmentally friendly hydrogen, electricity and integrated direct recovery plants, CO2 emissions from steel production will be reduced by 30%. For 2030, the company has already planned to produce such climate-neutral products almost 3 million tons.

Thanks to our partnership, Ukrainian farmers also contribute to the environment protection and absolute confidence in the purchased elevator equipment, even in the harshest operating conditions.

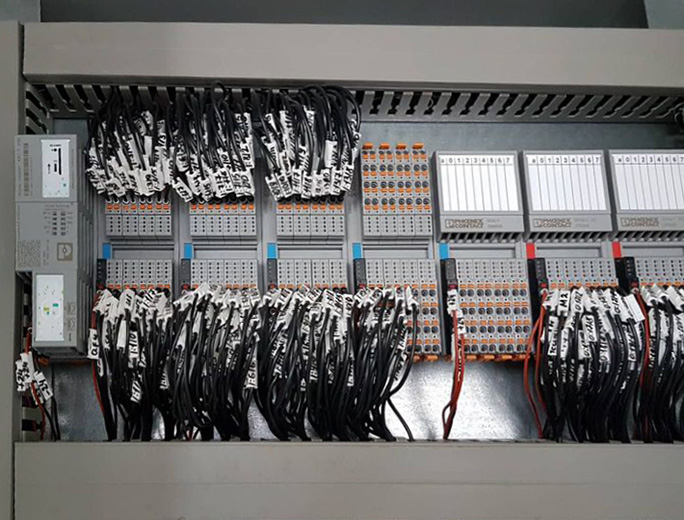

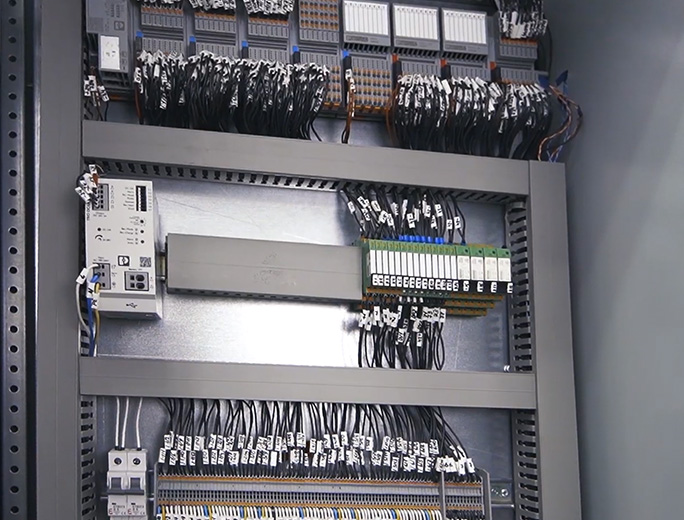

Accessories for control cabinets from Phoenix Contact

The control cabinets that KMZ Industries uses to automate Ukrainian grain storage facilities are manufactured at our factory from world-famous German electrical giant Phoenix Contact components, which in Ukraine is represented by Phoenix Contact Ukraine. The company’s global network is represented in more than 100 countries, 17,400 employees, annual turnover is more than 2 billion euros.

Why Phoenix Contact?

- Control devices for controllers, terminals, relays and peripherals manufactured by Phoenix Contact, which we use for manufacture of cabinets – all of them meet the highest standards, in particular: DIN standards (the German Institute for Standardization) and IEC standards (the International Energy Commission).

- All products of this manufacturer, without exception, pass the maximum possible number of tests for each type. For example, checking electrical connections necessarily includes 22 tests type, including: mechanical strength, bending, heating, corrosion, aging, short-term current resistance, voltage drop testing, vibration and impact resistance, temperature drop testing, salt mist atmosphere testing, and many others.

- Phoenix Contact even has its own formulations for the manufacture of plastics and metal alloys that they use in the conductive part of their electronics. Their terminals do not burn not only in the event of an overvoltage, but even when directly exposed to a direct flame: the plastic simply flows down in non-burning drops.

- BMW and Mercedes automated assembly lines are equipped this manufacturer with controllers, cyber protection and wireless technologies. The best – choose the best.

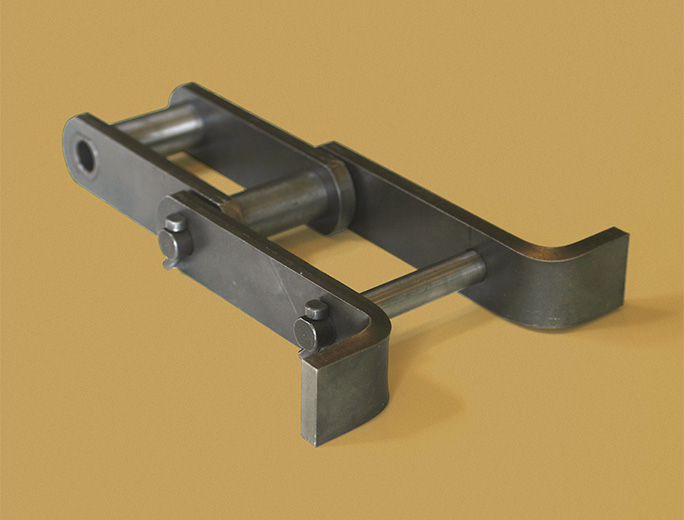

JOHN KING conveyor chains

Chains for our conveyors are supplied by the British manufacturer JOHN KING. In a few years, JOHN KING will celebrate centenary, and the company really should proud of yourself. At origin it was the UK coal industry mechanization, and later expanded its presence in other industries and achieved global leadership in the production of a wide range of transport chains.

Why transport chains from JOHN KING?

Fully robotic line with 100% quality control at every stage of chain manufacturing. And also improved technical characteristics, energy efficiency, high reliability and long service life – we consider this is really important for this component. And transport chains from JOHN KING fully meet these criteria!

We produce the best elevator equipment for you and provide it with the highest quality components so that you have really efficient elevator!

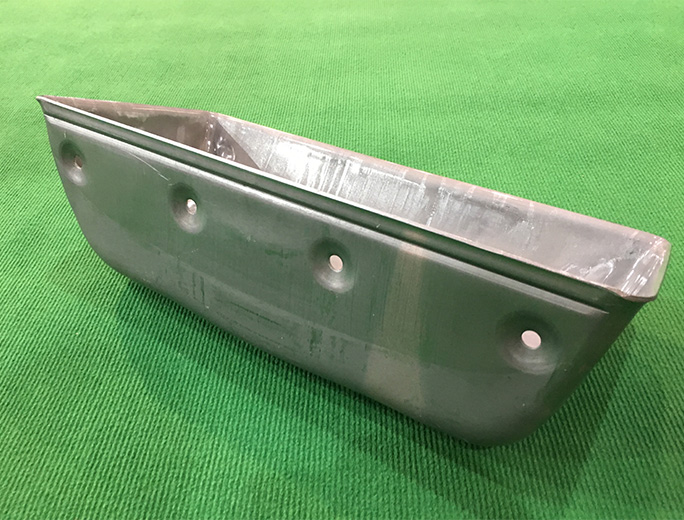

JET`s buckets of bucket elevators from STIF

Transport equipment is the elevator vital artery, so every detail is important here.

Regarding the complete own production set of bucket elevators, so here we also cooperate with the French company STIF. For several decades, this manufacturer has been known on the international market as the undisputed leader in the production of transport equipment components for bulk materials. Moreover, the quality has now been evaluated in 70 countries all around the world. So we can trust you!

Why JET`s buckets of bucket elevators from STIF?

- Greater performance. Buckets of bucket elevators produced by STIF`s have a patented form – this provides improved emptying performance of the moved product, which increases bucket elevators productivity in similar standard sizes with competitors.

- Less injury. In metal buckets, the bent edge less injures the transported product, which reduces the percentage of combat, and therefore reduces unnecessary losses for farmer when moving product.

- Minimize sticking. The geometry of the buckets contributes to uniform wear (after all, there are no places-stress concentrators) and minimizes sticking/retention of the product in bucket.

ALP-PROM Industrial climbing

The company ALP-PROM is engaged in comprehensive renovation of granaries with the use of industrial climbing, which allows to perform work in hard-to-reach and dangerous places with observance of safety rules.

POPULAR

OVER 5000 PROJECTS

DEVELOPED WORLDWIDE

CONTACTS

HEAD OFFICE

+38 (05346) 221 38

2 Sergii Nihoian St., Karlivka, Poltava region, 39500, Ukraine

SALES OFFICE

+38 (050) 435 76 97

sales@kmzindustries.ua ,

2V Mykilsko-Slobidska St., office 157, Kyiv, 02002, Ukraine