What is a grain storage complex with computer-assisted management?

- Cost-effectiveness management

- Reduction of primary capital expenditure

- Planning and control of capital and operating expenditures (OPEX)

- Single monitoring and control system for the group of storage complexes

To make all processes at the storage complex as much transparent and controllable as possible, and as a consequence – to manage its cost-effectiveness; exactly this task, assigned by the grain silo owner, is performed by the computer control complex solutions implemented by our company.

Why a grain storage complex should be automated?

- To ensure a continuous, transparent and controlled technological process and leverage of the equipment and machine capacity. This is achieved and implemented by applying routes sequencing management and the possibility of planning loading volumes.

- Accurately account for the received products, manufacturing expenses, etc.

- To control the quality of the grain, and as a result – its cost.

- To mitigate as high as possible a human factor impact and to prevent a fraudulent scheme.

- To reduce the expenditures during maintaining personnel hiring by downsizing the total staff number and reducing the need in terms of the provision by highly qualified specialists.

- To prevent equipment failure and ensure its timely maintenance.

Solutions for automated control of grain storage complex by KMZ Industries

KMZ Industries’ solution includes the following:

- Automation of the line grain storage equipment (hardware components and software).

- Temperature control.

- Monitoring and control of the weighing unit.

- Sample extractor and laboratory.

- Accounting and technical management.

- IT solutions, which visualize and integrate these processes into the unified management system.

Automation system of the grain storage complex

- Power supply cabinets (incoming line cabinets; power distribution cabinets; equipment control cabinets).

- Programmable controller cabinet (PLC cabinet; distributed peripheral cabinets).

- Communication hardware equipment.

- Cabinets of lighting.

- Operator’s automated workplace.

Hardware components aresupplied byleadingglobal brands (Siemens, Schneider, Eaton).

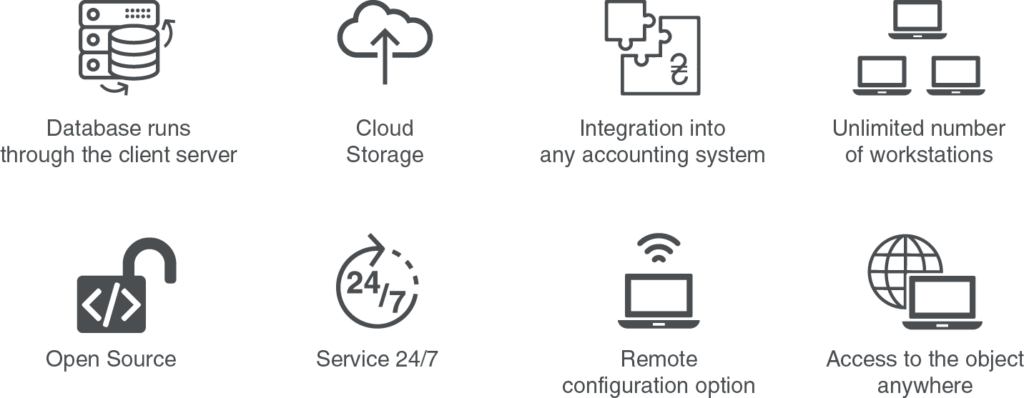

Unified control system of grain storage complex (IT and web solution):

- Homegrown software development.

- Basic software package is customized individually for each customer. It enables saving time on the development of the standard task and automates the operation-routing sequence, to control a grain dryer, a separator taking into account a specific elevator. Software of the visualization process is provided with open source.

Software solutions implemented on the PLCnext Technology platform are provided by PhoenixContact, a German electrical engineering giant.

DISTINCTIVE FEATURES OF IIOT-SOLUTION

1. Modularity.

- A unified platform with the possibility of the gradual or selective connection of the modules at the customer’s request.

2. Genericity and flexibility.

- A completed software package is adapted and adjusted to the requirements of a specific elevator. This significantly cuts expenses during commissioning and software development.

3. Overall simplicity.

- An intuitively comprehensible and user-friendly interface is adapted for non-qualified personnel.

4. Extensibility.

- Phoenix Contact PLCnext controller can be extended up to 63 modules on the one hardware bay, which allows you to save for purchasing the hardware part in case of increasing the connected modules to the solution.

Practical tips for automation of grain storage complex

1. Automated process control system designing

Automation of the grain storage complex starts with the construction of a transparent and efficient processing chain.

Design availability allows the following:

- Estimate the number of materials and devices to be used.

- Make an assessment (plan) a budget.

- Obtain a permit for operation.

Automation without a design increases the implementation cost 2 times. Investments in the design development save up to 50% of the budget of such implementation, because of future modifications and alterations (materials, services) absence.

It is significantly important to design a complex solution for future reference. It can be implemented stage-by-stage, in the following order: safety of the conveyor line, separator, and grain dryer, which are responsible for the grain quality; grain receiving to exclude a fraudulent scheme.

2. Automation of the existing grain storage complexes

It’s possible to implement the automation system both at the new and the existing elevator without the necessity of closing down operations and without reference to the season.

Above that, НАССР (Hazard Analysis and Critical Control Points) at the storage complex also requires complete automation of the processes, which is mandatory for the industrial facilities engaged in activities with food substances.

3. Implementation terms and return on investment

Turnkey automation of the elevator complex with a capacity of 40 000 tons of one-time storage takes 3-4 months, from the technological flows programming work to equipment assembly and software installation at the facility.

The term of the return on investment of the fully-automated elevator is 1.5 years shorter in comparison with a similar non-automated elevator. This is achieved by cutting off the expenses on personnel, reducing energy consumption and optimizing the operation-routing sequence.

15% of the resources from the annual turnover on operating costs are released.

Why KMZ Industries?

KMZ Industries specializes in the automation of grain storage complexes because we understand grain storage and processing technology.

- We manufacture grain storage and handling equipment.

- We automate it and technological processes at the complexes.

- We combine all processes into a unified system.

A properly implemented automation enables you full access to your grain storage complex, wherever you are. It allows you to completely control a situation: from the smallest detail up to all process flow, e.g. to manage directly with your profit.

Projects

POPULAR

OVER 5000 PROJECTS

DEVELOPED WORLDWIDE

CONTACTS

HEAD OFFICE

+38 (05346) 221 38

2 Sergii Nihoian St., Karlivka, Poltava region, 39500, Ukraine

SALES OFFICE

+38 (050) 435 76 97

sales@kmzindustries.ua ,

2V Mykilsko-Slobidska St., office 157, Kyiv, 02002, Ukraine