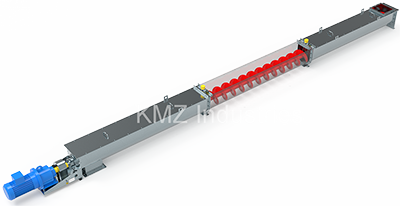

KG screw conveyors

Production

capacity up to

200

t/h

Placed at an

angle up to

60°

KG screw conveyors

KG screw conveyors by KMZ Industries

KG series screw conveyors are designed for horizontal or inclined transportation of grain and its products.

Screw conveyors safeguard the enclosed process of product transportation, capability to load and unload in several points, zero loss of transported grain, reversible product feed, security during maintenance and repairs, low energy consumption.

The design of KG screw conveyors envisages the thermal compensation of the screw in axial direction along with the bearing assemblies mounted outside the casing, enabling the transportation of materials with a temperature of up to 90°C.

Radial roller bearings are used in the bearing assemblies, which enables the transportation of high-density materials (sand, cement, etc.). The ability to quickly replace the friction parts without disassembling the conveyor itself is foreseen by the constructive design of the hanger bearings.

Screw conveyors stand out with their usability in nearly all industry sectors.The various technical processes (for instance mixing, heating, cooling, moisturizing) can be deliberately combined in the production process with transportation.Transportation does not involve dust and smell due to the complete sealing of the housing.

Simple integration with the system as a whole, because loading and unloading are possible anywhere.

The structure does not need a large production area.

Conveyors distinctive features:

- Production capacity up to 200 t/h.

- May be placed at an angle of up to 60°.

- Reversible product feed.

- Transportation of loads with temperatures up to 90 °C due to temperature compensation of the auger.

- Quick replacement of friction parts without dismantling the entire conveyor.

- Ability to transport products with a higher density due to the roller angular bearings.

- The product is transported without dust and odour due to the complete sealing of the box.

Please contact us for any questions you may have concerning our company, products or services.

Fill out the feedback form or call +38 (050) 435 76 97.

Advantages of KMZ INDUSTRIES Conveying Equipment

Prolonged service life

Design compatible with any kind of automation system

Monitoring systems minimize interference by staff

Selection of energy-saving drivers (up yo 30% of resource saving)

System of electro/explosion/vibro/environmental security

Convenience of maintenance and repair

Maximum sealing of joints

Bearing assemblies from leading European manufacturers

Ease and speed of assembly

Other types of Conveying equipment

Projects

POPULAR

OVER 5000 PROJECTS

DEVELOPED WORLDWIDE

CONTACTS

HEAD OFFICE

+38 (05346) 221 38 , 2 Sergii Nihoian St., Karlivka, Poltava region, 39500, Ukraine

SALES OFFICE

+38 (050) 435 76 97 , sales@kmzindustries.ua , 2V Mykilsko-Slobidska St., office 157, Kyiv, 02002, Ukraine